Vacuum sealing is an excellent method to extend the shelf life of your food and keep it fresh for longer. By removing air from the packaging, vacuum sealing helps prevent spoilage and freezer burn. However, several common vacuum sealing mistakes can compromise the effectiveness of this preservation technique. To ensure optimal results, it’s essential to be aware of these avoidable vacuum sealing errors.

Problems can arise during the bagging and sealing process, leading to food spoilage or reduced storage quality. In this article, we will explore the most common vacuum sealing mistakes and share valuable tips and tricks to help you avoid them.

Key Takeaways

- Choose the right vacuum sealer for your needs and ensure compatibility with the bags you will be using.

- Use textured vacuum bags with an oxygen barrier to facilitate proper air removal and sealing.

- Maintain proper hygiene by washing hands or wearing gloves during the vacuum sealing process.

- Allow items to cool before vacuum sealing to prevent condensation and moisture buildup.

- Do not overfill the bag; leave room for air removal and sealing.

Choose the Right Sealer

The first step in vacuum sealing is choosing the right sealer for your needs. Whether you’re vacuum sealing for home use or commercial purposes, selecting a suitable vacuum sealer is crucial for achieving optimal results.

“Choosing the right sealer is essential to ensure the effectiveness and efficiency of the vacuum sealing process.” – Home Kitchen Magazine

If you’re planning to vacuum seal items at home, it’s important to consider the specific requirements of your sealing needs. Ensure that the sealer you choose is compatible with the bags you will be using and can accommodate the size and type of items you want to preserve. For example, if you wish to vacuum seal liquids or foods in jars, opt for a sealer specially designed for this purpose.

On the other hand, if you’re looking for a commercial vacuum sealer, there are additional factors to consider. Speed, efficiency, and durability become crucial when dealing with larger volumes and more demanding operations. Choose a sealer that can handle the higher workload and meet the requirements of your commercial vacuum sealing needs.

Remember to consider the specific features and capabilities of the vacuum sealer to ensure it aligns with your specific needs, be it home-use vacuuming or commercial vacuum sealing.

By selecting the right sealer, you can ensure a successful vacuum sealing process and extend the shelf life of your preserved items.

Comparison of Home-Use and Commercial Vacuum Sealers

| Home-Use Vacuum Sealers | Commercial Vacuum Sealers | |

|---|---|---|

| Key Features | Compatible with home-use vacuum bags Accommodates smaller volumes Designed for a wide range of home preservation needs | Handle higher volumes Designed for more demanding operations Offer faster sealing speeds |

| Suitable for | Preserving leftovers Sealing individual portions Vacuum sealing non-liquid items | Food service industry Restaurant kitchens Butcher shops and delis |

| Durability | Designed for occasional use at home Suitable for regular household needs | Built to withstand extensive use Can handle frequent vacuum sealing operations |

| Sealing Capacity | Accommodates smaller quantities May have size limitations Varies based on the specific model | Accommodates larger quantities Capable of handling higher volumes Can accommodate larger bags |

Table provides a comparison between home-use and commercial vacuum sealers, highlighting key features, suitable applications, durability, and sealing capacity.

Use Compatible Vacuum Bags

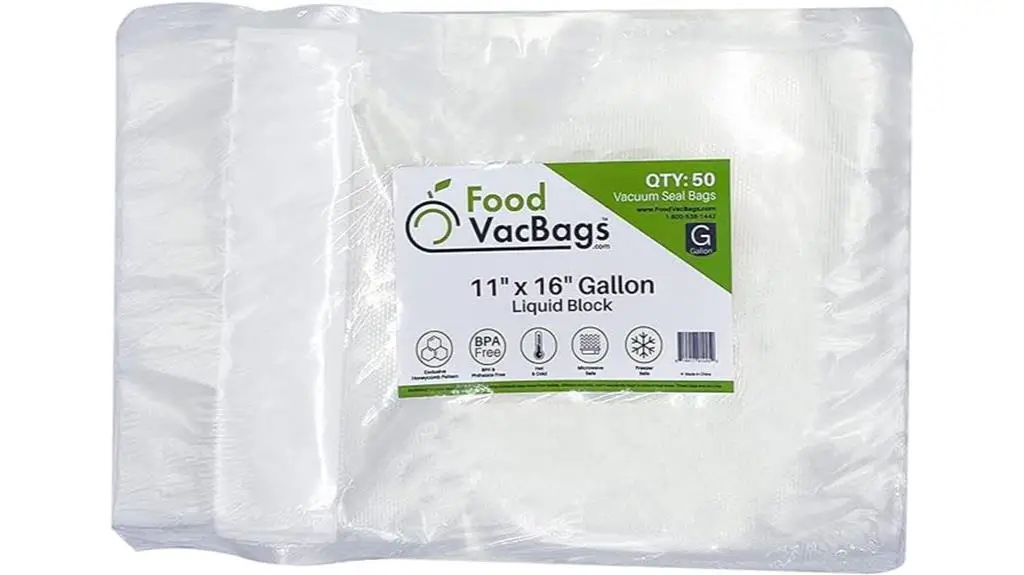

When using a home-use vacuum sealer, it is crucial to use vacuum bags that have textured channels. These textured vacuum bags allow air to escape and run out of the bag as a vacuum is pulled, which is essential for proper sealing.

Avoid purchasing smooth replacement vacuum bags or regular poly bags, as they will not hold a vacuum. Vacuum bags have an oxygen barrier that keeps air from entering or escaping after a seal has been made, so make sure any bags or rolls used with your sealer have this oxygen barrier.

Wash Hands or Wear Gloves

To maintain cleanliness and prevent bacteria from contaminating the food being vacuum packaged, it is crucial to practice proper hand washing or wear gloves when coming into direct contact with the product. This step is particularly important when dealing with cooked food that only needs to be warmed, as bacteria may not be completely eliminated through insufficient heating. By keeping hands clean or wearing gloves, you can ensure a clean and sanitary vacuum sealing process.

Proper hand washing involves using warm water and soap, and vigorously rubbing hands together for at least 20 seconds, making sure to clean all areas including the fingers, palms, and wrists. After thoroughly washing, dry hands with a clean towel or air dryer.

If you prefer to wear gloves, choose disposable food-grade gloves that fit well and ensure freedom of movement. Avoid using gloves made from latex if you or anyone you are serving has latex allergies. Before wearing gloves, make sure your hands are clean. Dispose of the gloves properly after use, and never reuse disposable gloves.

Whether you opt for hand washing or wearing gloves, it’s important to remember that both methods contribute to maintaining a clean and sanitary environment for vacuum sealing your food items.

Allow Items to Cool Before Vacuum Sealing

When vacuum sealing food, it is crucial to consider the temperature of the items being sealed. Warm or hot food can cause condensation to form inside the vacuum-sealed bags, leading to moisture buildup and potentially resulting in freezer burn. To prevent this, it is important to allow the items to cool down before sealing them in vacuum barrier bags.

By allowing the food to cool, you minimize the chances of moisture accumulating inside the bag, which can degrade the quality of the food over time. Cooling the food also helps maintain the maximum freshness and flavor when it is eventually consumed.

| Benefits of Allowing Items to Cool Before Vacuum Sealing | Drawbacks of Not Allowing Items to Cool Before Vacuum Sealing |

|---|---|

|

|

By allowing your food to cool down before vacuum sealing, you can ensure that it stays fresh and free from moisture-related issues. Take the time to let your items reach room temperature before sealing them to enjoy the full benefits of vacuum sealing.

Do Not Fill the Bag All the Way

When vacuum sealing, it is important to leave room at the top of the bag for air removal and sealing. Whether you’re sealing dry goods or liquids, providing sufficient space is essential for a successful seal and preventing leakage.

If you’re sealing bags that contain juices or liquids, it becomes even more crucial to leave extra space. Different vacuum sealers may require different amounts of room for sealing, especially when dealing with liquids that can be easily displaced during the sealing process.

By leaving enough room at the top of the bag, you allow the excess air to be effectively removed, ensuring a tight seal. This not only prevents potential leakage but also helps maintain the freshness and quality of the sealed contents.

Wipe Off Liquids and Particles Before Sealing

Before placing consumable items in the bag, it is important to remove any residue or juices from the top section of the bag. Using a paper towel, wipe off any small food particles or excess liquids that may hinder the sealing process. If there is noticeable residue or liquid at the top of the bag where the seal is made, take the extra time to wipe it off to ensure a proper seal.

Why is it important to wipe off residue?

The residue on the bag, such as food particles or juices, can impede the seal and compromise the effectiveness of vacuum sealing. These residues can prevent the bag from properly adhering to the sealer, leading to air leakage and a weakened seal. By wiping off any liquids and particles, you can ensure a clean and optimal seal.

Make Sure the Bag is Properly Aligned Within the Vacuum Sealer

Ensuring the correct placement of the bag within the vacuum sealer is crucial for achieving a proper seal. Different types of vacuum sealers, such as nozzle sealers, edge sealers, and larger chamber vacuum sealers, have specific requirements for bag placement during the sealing process.

Nozzle sealers require the nozzle to be placed at a specific depth in the bag. This ensures proper air removal and sealing. Incorrect placement may result in air leakage, compromising the freshness and longevity of the sealed items.

Edge sealers, on the other hand, require the bag to be positioned in a specific area for efficient air removal and sealing. Placing the bag incorrectly may lead to incomplete sealing, allowing air and moisture to enter, which can lead to food spoilage or freezer burn.

Larger chamber vacuum sealers also have specific placement requirements for the end of the package. Proper alignment ensures that the bag is placed in the optimal position to achieve a tight seal and maintain the vacuum for an extended period.

To achieve the best results with your vacuum sealer, carefully follow the manufacturer’s instructions regarding bag placement. By doing so, you can maximize the effectiveness of the sealing process and ensure the long-term freshness and quality of your vacuum-sealed items.

Inspect the Vacuum Bag After a Seal has been Made

Once you’ve sealed the vacuum bag, it’s essential to visually inspect the seal seam for any spots or wrinkles. These imperfections can compromise the airtight seal and result in air exposure, leading to a loss of vacuum. Additionally, wrinkles or creases in the seal can cause leakage, allowing air and moisture to enter the bag and potentially spoil the contents.

To ensure the seal is secure, it’s recommended to perform a simple test. Give the seal a firm pull, checking for any signs of weakness or separation. A properly sealed bag should be difficult to pull apart without tearing. By testing the seal, you can verify its strength and ensure the preservation of your items for an extended period.

Inspect the Sealing Area After Each Use

After multiple seals have been made, it is common for juice and other components to harden and build up on the sealing wire. This buildup can impede sealing and reduce the effectiveness of the wire over time. It is important to clean the sealing area after each use with a lightly dampened cloth to ensure optimal sealing wire life. Additionally, if any areas of the Teflon cover are torn or ripped, replace the Teflon tape to maintain proper sealing performance.

| Common Issues with Sealing Area | Solutions |

|---|---|

| Buildup on the sealing wire | Clean the sealing area after each use with a lightly dampened cloth. |

| Torn or ripped Teflon cover | Replace the Teflon tape. |

Conclusion

By following these tips and avoiding common vacuum sealing mistakes, you can ensure that your stored items are completely sealed and protected from spoilage or freezer burn. Choosing the right sealer and using compatible vacuum bags are essential for preventing vacuum sealing errors. Practicing proper hygiene, allowing items to cool before sealing, and leaving room for air removal and sealing are crucial steps to maintaining food freshness. Wiping off liquids and particles, aligning the bag correctly within the sealer, and inspecting the seal after it has been made will further enhance the sealing process.

Regularly inspecting and cleaning the sealing area, as well as replacing torn Teflon tape, will help maintain optimal sealing wire performance and prevent any vacuum sealing errors. By implementing these tips and best practices, you can extend the shelf life of your food, reduce waste, and ultimately save on food costs. Vacuum sealing provides a cost-effective way to preserve your food, ensuring its freshness and quality for longer periods.

Remember, preventing vacuum sealing errors is key to maintaining the freshness and quality of your food while also saving on food costs. By adopting proper techniques and using high-quality vacuum sealing equipment, you can enjoy the benefits of vacuum sealing and extend the shelf life of your favorite food items.

FAQ

What are the top vacuum sealing mistakes to avoid?

Avoidable vacuum sealing errors include using the wrong sealer, using incompatible vacuum bags, not practicing proper hygiene, sealing warm food, overfilling the bag, failing to wipe off liquids and particles, misaligning the bag within the sealer, not inspecting the seal, neglecting to clean the sealing area, and not replacing torn Teflon tape.

How do I choose the right sealer for vacuum sealing?

When selecting a vacuum sealer, consider factors such as the compatibility with the bags you plan to use, the size and type of items you want to preserve, and the specific requirements for sealing liquids or foods in jars. For commercial use, also consider speed, efficiency, and durability.

What type of vacuum bags should I use?

It is important to use vacuum bags with textured channels that allow air to escape during the sealing process. Avoid using smooth replacement vacuum bags or regular poly bags. Make sure the bags or rolls you use have an oxygen barrier to prevent air from entering or escaping after sealing.

Should I wash my hands or wear gloves when vacuum sealing?

Yes, it is recommended to wash your hands or wear gloves when coming into direct contact with the food being vacuum sealed. This helps maintain cleanliness and prevents the transfer of bacteria that can contaminate the food and cause spoilage.

Why is it important to allow items to cool before vacuum sealing?

Warm food can create condensation inside the vacuum-sealed bag, leading to moisture buildup and potentially causing freezer burn. Allowing items to cool before sealing reduces the chances of moisture accumulation and helps preserve the quality of the food.

How much should I fill the vacuum bag?

It is important to leave some room at the top of the bag for air removal and sealing. Different sealers may require different amounts of space, especially when dealing with bags containing liquids. Leaving enough space ensures proper air removal, heat sealing, and prevents potential leakage.

Should I wipe off liquids and particles from the top of the bag before sealing?

Yes, it is recommended to wipe off any residue or juices from the top section of the bag before sealing. Using a paper towel, remove small food particles or excess liquids that may hinder the sealing process. This ensures a proper seal and prevents potential leakage.

How should I align the bag within the vacuum sealer?

Each vacuum sealer has specific requirements for bag placement during the sealing process. Nozzle sealers require the nozzle to be placed at a specific depth in the bag, while edge sealers require the bag to be placed in a specific area for air removal and sealing. Larger chamber vacuum sealers also have specific placement requirements. Proper alignment is crucial for achieving a proper seal.

Why should I inspect the vacuum bag after a seal has been made?

After making a seal, visually inspect the seal seam for spots or wrinkles. Spots that do not seal properly can result in air exposure and loss of vacuum, while wrinkles or creases can cause leakage. Test the seal by giving it a firm pull. A properly sealed bag should be difficult to pull apart without tearing.

How often should I inspect the sealing area and clean it?

It is recommended to clean the sealing area after each use with a lightly dampened cloth to remove any buildup on the sealing wire. Regularly inspect the sealing area for any torn or ripped Teflon cover. If any damage is found, replace the Teflon tape to maintain optimal sealing wire performance.

What are the benefits of following these vacuum sealing tips?

By avoiding common vacuum sealing mistakes and following these tips, you can ensure that your stored items are properly sealed and protected from spoilage or freezer burn. This will help extend the shelf life of your food, reduce waste, and save on food costs.

Last update on 2026-02-26 / Affiliate links / Images from Amazon Product Advertising API